What are the requirements of the chemical industry for hydraulic tubing

Release time:

2023-11-27

The chemical industry may have stricter requirements for hydraulic tubing than other industries, because the working environment of the chemical industry is usually poor, and there are special conditions such as high temperature, high pressure, and corrosion. The following are some of the main requirements for hydraulic tubing in the chemical industry:

The chemical industry may have stricter requirements for hydraulic tubing than other industries, because the working environment of the chemical industry is usually poor, and there are special conditions such as high temperature, high pressure, and corrosion. The following are some of the main requirements for hydraulic tubing in the chemical industry:

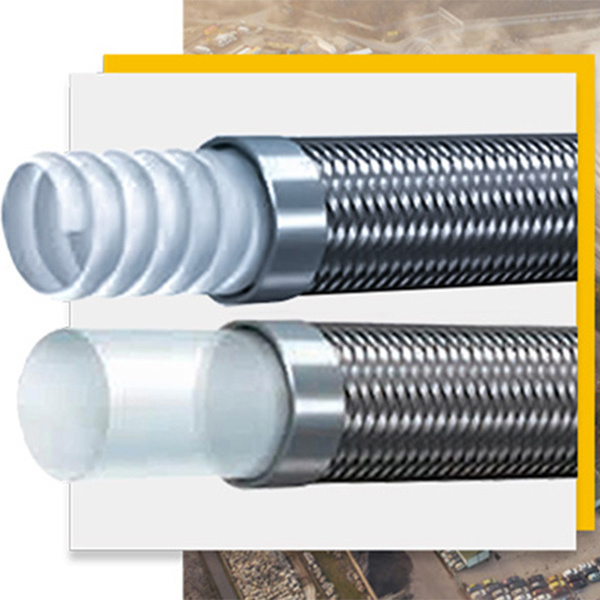

1. Corrosion resistance: In the chemical industry, liquids and gases are usually corrosive, so hydraulic tubing needs to have good corrosion resistance. Common hydraulic tubing materials include stainless steel, acid and alkali resistant steel, nickel alloy, etc. These materials can resist the erosion of chemical substances and ensure the reliability of hydraulic system.

2. The working temperature in the chemical industry is often high, so the hydraulic oil pipe needs to have good high temperature resistance. Some special high-temperature hydraulic oil pipes usually use high-temperature alloy materials, such as chromium-molybdenum alloy steel and nickel-based alloy. These materials can maintain good strength and corrosion resistance in high temperature environments.

Anti-static characteristics: In the chemical industry, some working environments will accumulate static electricity. If the hydraulic tubing does not have good anti-static characteristics, it will have a negative impact on the safety and stability of the hydraulic system. Therefore, the chemical industry usually requires hydraulic tubing with good anti-static properties to reduce the risk of static accumulation.

4. Pressure capacity: In the chemical industry, hydraulic systems are usually required to withstand high pressures, requiring hydraulic tubing to have good pressure resistance. This requires the selection of high-strength materials, and to ensure that the manufacturing process and connection methods meet the requirements to ensure the reliability and safety of the system.

5. High sealing requirements: In the hydraulic system of the chemical industry, the sealing requirements of the hydraulic oil pipe are high to prevent leakage and pollution. In order to achieve a good sealing effect, you can choose the appropriate seal and connection.

To sum up, the chemical industry has the following requirements for hydraulic tubing: corrosion resistance, high temperature resistance, anti-static function, and must have pressure resistance and good sealing performance. When selecting the material and technology of the hydraulic oil pipe, it should be carried out according to the specific working environment and process requirements, and ensure compliance with relevant standards and specifications to ensure the safe and reliable operation of the hydraulic system.

More information